'What the smelter, smith and alchemist have in common is that all three lay claim to a particular magico-religious experience in their relations with matter; this experience is their monopoly and its secret is transmitted through the initiatory rites of their trades. All three work on a Matter which they hold to be at once alive and sacred, and in their labours they pursue the transformation of matter, its perfection and transmutation.' - M. Eliade

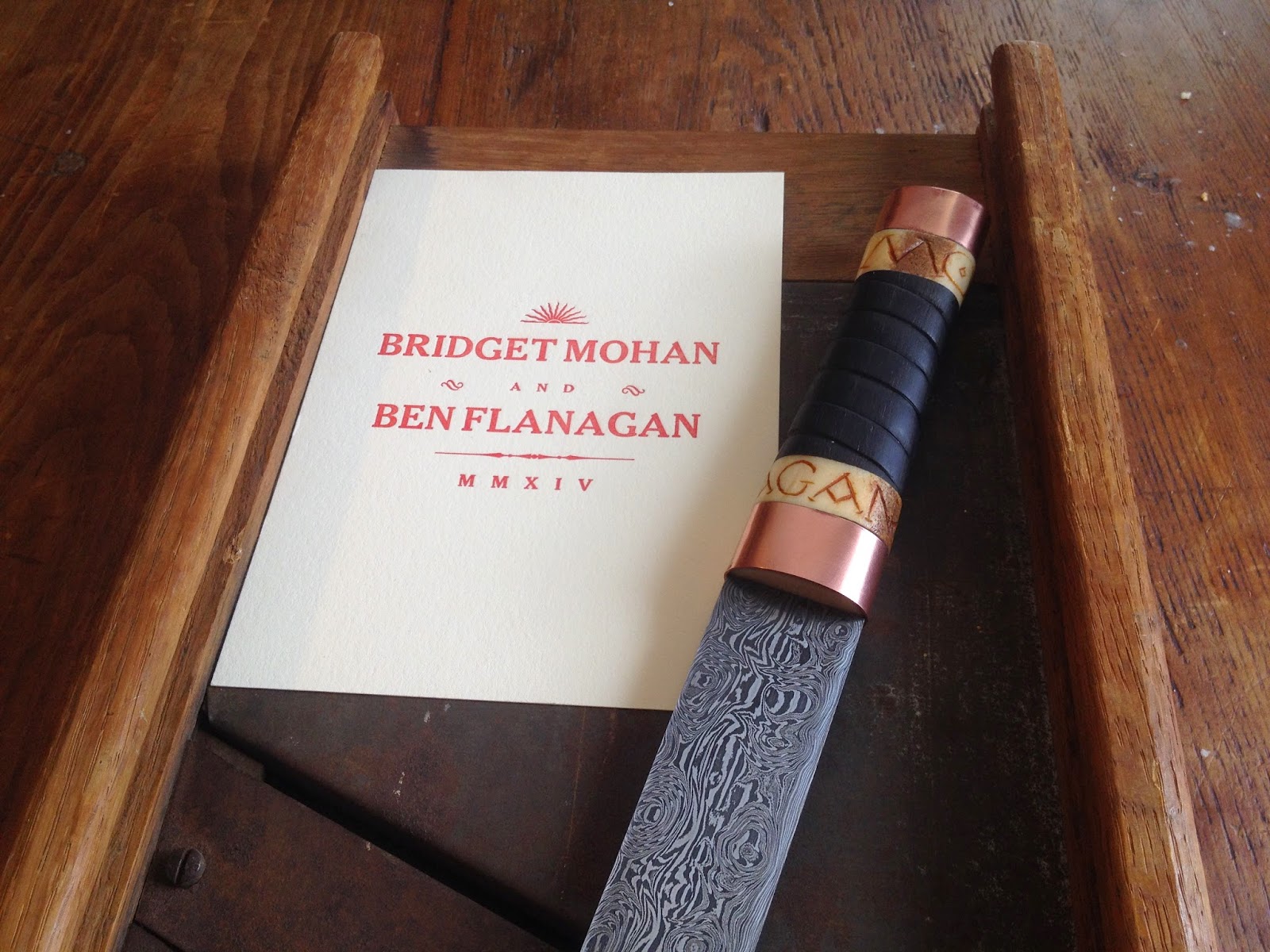

The iron-working smith is shaped by their relationship with a material that often develops into a philosophy of experience indelibly changed by the idea of iron. The bladesmith, arguably more than most other smiths, works to push the limits of iron and steel, delving deep into their genetic attributes and attempting to alter them to their own ends: supernatural standards of hardness, flexibility, complexity and beauty.

The blacksmith is concerned primarily with form; the bladesmith as well, but just much with substance. The material of both smiths starts with the iron-maker smelting from ores, but the blade-maker must understand these processes from start to finish. What goes into the creation of steel, what goes into working it in time and temperature, form and finish is imperative in every measure. The standards of what a blade is and does are at once vague and very specific. For every blade that has ever been made, the process is complex; similar yet different every time, and ultimately concerns the learned transformation of materials in a seemingly magical, elemental transformational process.

The natural state of iron on earth is transformation into iron oxides, or rust. More than any other kind of smith, the bladesmith is very much concerned with reversing this process.This reversal is the process whereby iron is made from ores in the smelter's furnace; it is when firescale is scraped off to foster forge-welds. Reduction is the opposite of oxidation. Rust is the foe of the finished object as well, destroying beauty and function at once. As long as a blade is being created and used, growing and living, its makers and users fight against oxygen's effects. They scrub with stones and oils to preserve the substance, and preserve the form by sighting down lines to make sure they are true.

Until its day comes. Until the yarns of its fate have run off the spindle, as does that of every named thing. If it has a name, it has a purpose and it has a life. These must end. Just because a thing does not breathe with lungs does not mean it escapes the jurisdiction of time; its numbered breaths are on a different measure. All things of this earth are constantly in flux: we are growing, as we age; we die as we age, and why would we think that the state of death is permanent either? It is another passage which we cannot choose to avoid, through which we must change like any other passage. It is a process of initiation and transformation.

A blade is true, a blade is sharp, a blade shines with the light of day. Until its time as a blade is over. Then there is another initiation, another transformation, to ready it for the next world.

When our time-yarn runs out, we are surrounded by those who know the meaning of our name and who would see us out of this world into what lies next. In our ships, in our coffins, they prepare us to pass the gates. With ritual, with love, care, duty, and sacrifice, they destroy us. They surrender us to the elements; fire, water, earth, or open air: these will each break us down into what the earth loaned us, the corporal vessels our souls borrowed, and we will become the soil and water that sustained our bodies and will sustain those of our children's children. They will eat of our bodies and drink of our blood, and we will live on in them even as we fare out onto planes they only dream on.

Our rituals are prayers for growth, for birth, for seed, for strength. Time will not yield these without proper sacrifice. We must sow now if we are to reap later. We must give ourselves to the earth for our offspring to grow and live their days. We must carefully and sacredly cultivate growth and creation. To do that, we must observe and venerate rituals of destruction and decay, recognizing it as absolutely an equal process. This is the basis of all physics and chemistry; this is the basis of all alchemy and magic. They are all based on the same rule, which transcends and permeates all systems.

A smelter and a smith will spend a lifetime honing their skills at the reduction of iron oxides into iron; the perfecting of alloys; the treatment of steel; the exhibition of perfect substance, beautiful patterns, natural and intended (always a blend of both). There is a reason the grain of wood and the flow of rivers manifest themselves in the patterns of steel. There are sacred, underlying patterns at work: call them mathematics, call them intelligent design: they are the same. It is to these patterns, likewise superimposed on time, that we and our objects must be surrendered.

Creation is a science, an art, a ritual: all of these and never just one. There is an entire other side it relies on: destruction. All elemental bodies composed with a soul and traveling under a name are subject to the cycles of nature and time. Destruction is likewise a science; why not a ritual? Why not an art?

Is rusting not as fruitful a process as smelting? In truth it is; without rust, there would be nothing to smelt. The birth of iron lies in its own death, as with anything else. Why is bending not as beautiful as straightening? It is, when it is intentional. The smith spends a lifetime perfecting form and finish. But straightness and shine are not forever; neither should they be. The time must come when the passing of a threshold necessitates further change of form and substance. Iron must become rust. A blade must become not a blade. The cycle cannot be broken.

And so we worship creation and destruction in equal measure. We rejoice in birth and mourn in death, and cannot have one without the other. Likewise our iron comes tearing into the world from the dark mother in a storm of flames and air, and we surrender it to her deep earth and roaring waters, like we do our own shells when our souls have flown. There are patterns at play in the movements of stars and planets, in the lay of soils and rivers, in the lives of people and things. We have honored these since we first could in whatever ways we know, and it is not time to stop.