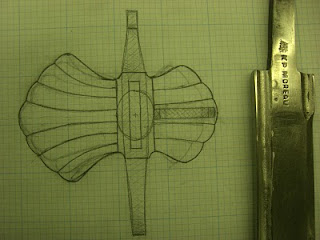

This is a picture of the outline I made of the flat piece that needs to be cut from 14 gauge sheet steel with the plasma cutter. We scanned this picture onto Torchmate CAD and prepared it to be sent to the cutter, which we'll do tomorrow!

This is a picture of the outline I made of the flat piece that needs to be cut from 14 gauge sheet steel with the plasma cutter. We scanned this picture onto Torchmate CAD and prepared it to be sent to the cutter, which we'll do tomorrow!Above it is the blade we're mounting. It's a beauty.

Stamped onto the blade when it was hot is the signature of the late bladesmith Kevin Moreau, a friend of Don's from Vermont. This is the chosen signature method of period smiths; something I'll do when I begin to forge my own blades is make a maker's mark stamp, or else etch my name into the blade with nitric acid, a process I'll go into when I try it. Right now I'm trying to gain access to some of that volatile substance from Cole Science Center, but chances are pretty low I'll get it.

Stamped onto the blade when it was hot is the signature of the late bladesmith Kevin Moreau, a friend of Don's from Vermont. This is the chosen signature method of period smiths; something I'll do when I begin to forge my own blades is make a maker's mark stamp, or else etch my name into the blade with nitric acid, a process I'll go into when I try it. Right now I'm trying to gain access to some of that volatile substance from Cole Science Center, but chances are pretty low I'll get it.Another method of signature and blade ornamentation I would love to experiment with is wire inlay, where annealed wire is hammered into chiseled grooves in the blade, and the excess is ground off. Again, I'll give this a sound explanation when I work my way up to it.

The shell guard of the sword (as seen in the picture from the Armour Class website) is to be cut from 14 gauge sheet steel. Here is a picture of my trial scalloping with a file, which I'll do on the shell guard when it's cut:

The shell guard of the sword (as seen in the picture from the Armour Class website) is to be cut from 14 gauge sheet steel. Here is a picture of my trial scalloping with a file, which I'll do on the shell guard when it's cut:

And here is a picture of what the end of the D-guard will look like, which I will hand-forge out of rectangular mild-steel bar stock. I took a while to get down the general idea of how to forge this shape:

FYI, Kev is not "late" but alive and well and makin period locks. Youcan see his work at Ironlocks.com. He taught me Damascus and swordsmithing in the early '90's.

ReplyDeleteWow thank you, I completely forgot that I had written that. I confused a story of Don's I believe; I have since visited Kevin and seen his incredible work in person, and he is a fantastic guy! Also, yes, very much alive haha. Good catch, don't want to spread rumours on the internet!

Delete